Dual-Chamber Absorption Systems with Complete Monitoring for Research & Industrial Applications

Our specialized iodine air filtration and absorption system is engineered for university research laboratories and industrial applications. Featuring two independent absorption chambers, integrated nitride removal, air dehydration, electrical heating, and comprehensive sensor monitoring, this system provides unparalleled flexibility for experimental research while maintaining industrial-grade performance. With dual sampling ports for real-time analysis and modular components for easy reconfiguration, it's the ideal solution for academic research, teaching laboratories, and specialized industrial iodine removal applications.

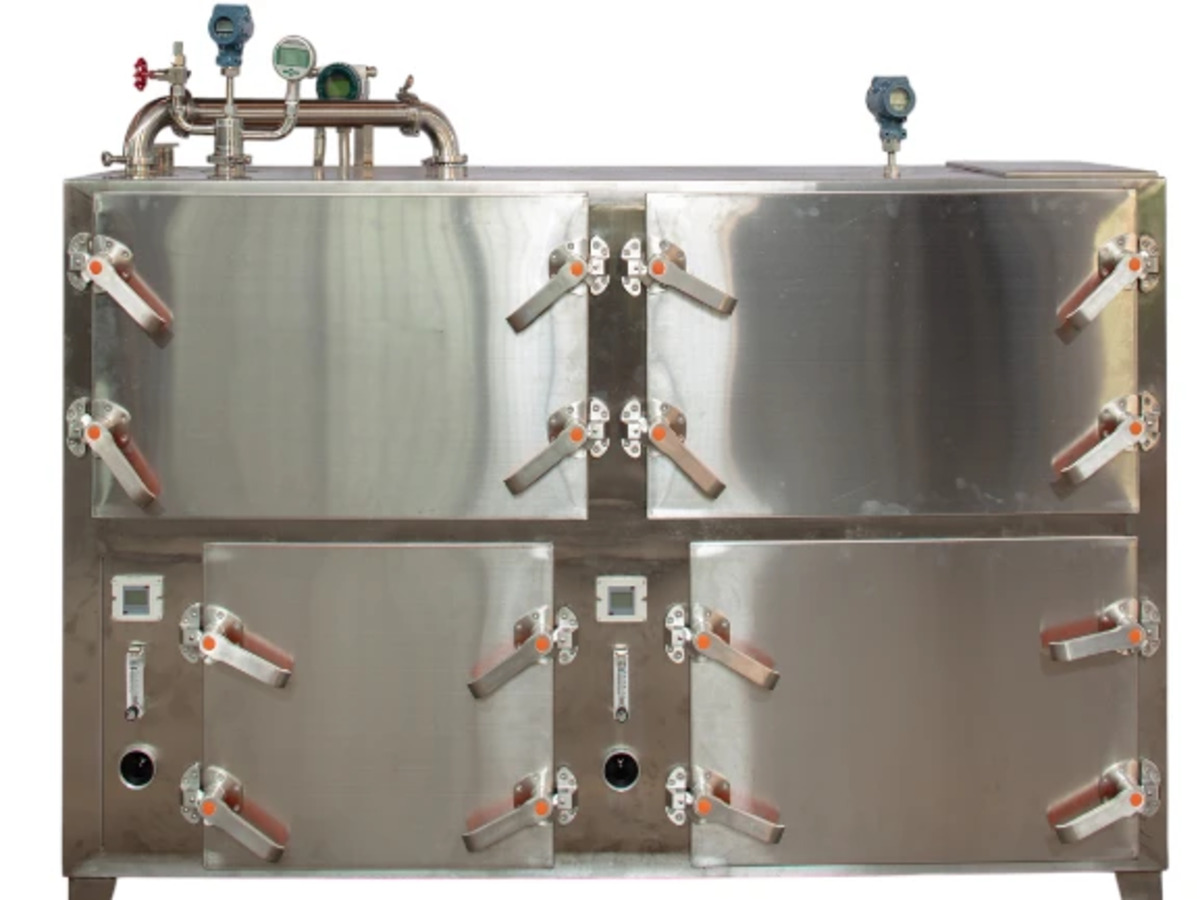

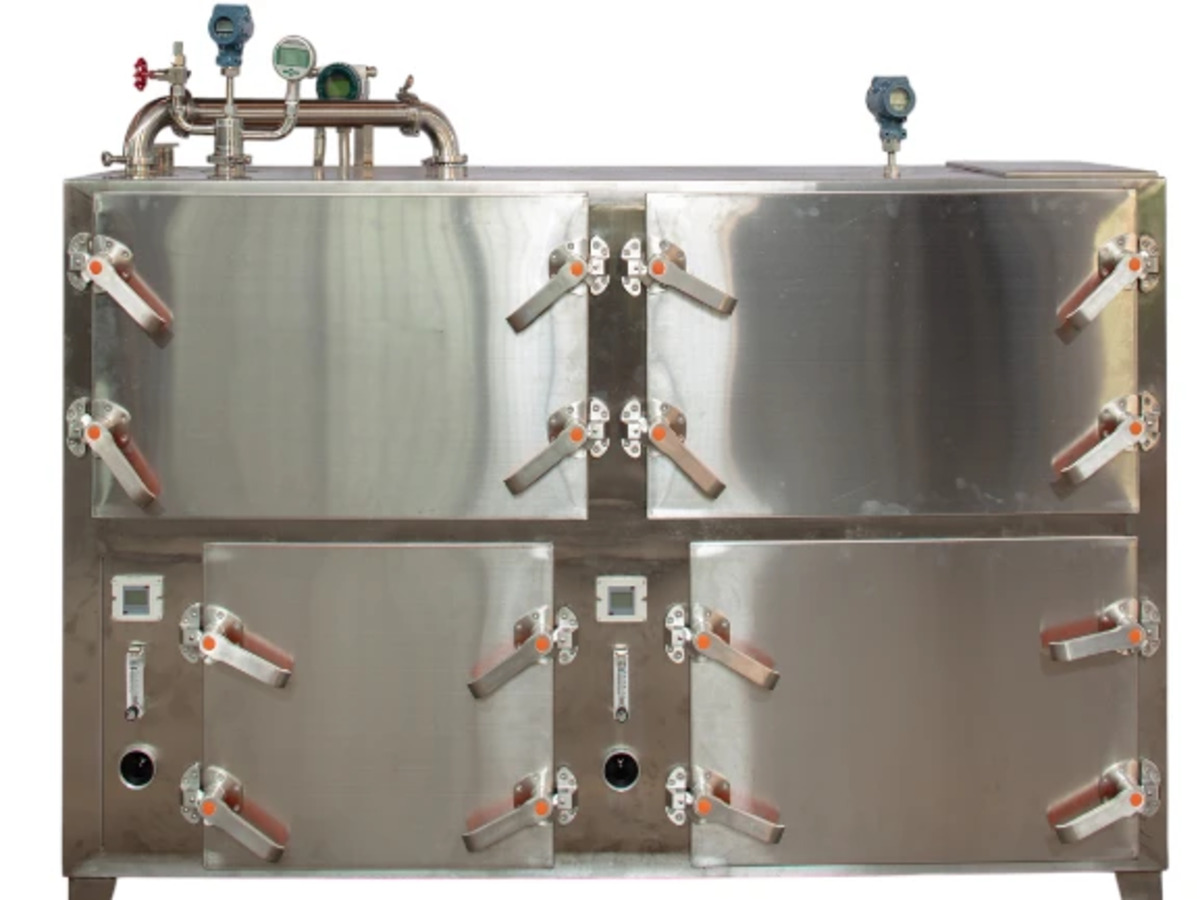

Modular iodine absorption system with integrated monitoring and experimental capabilities for research and industrial applications

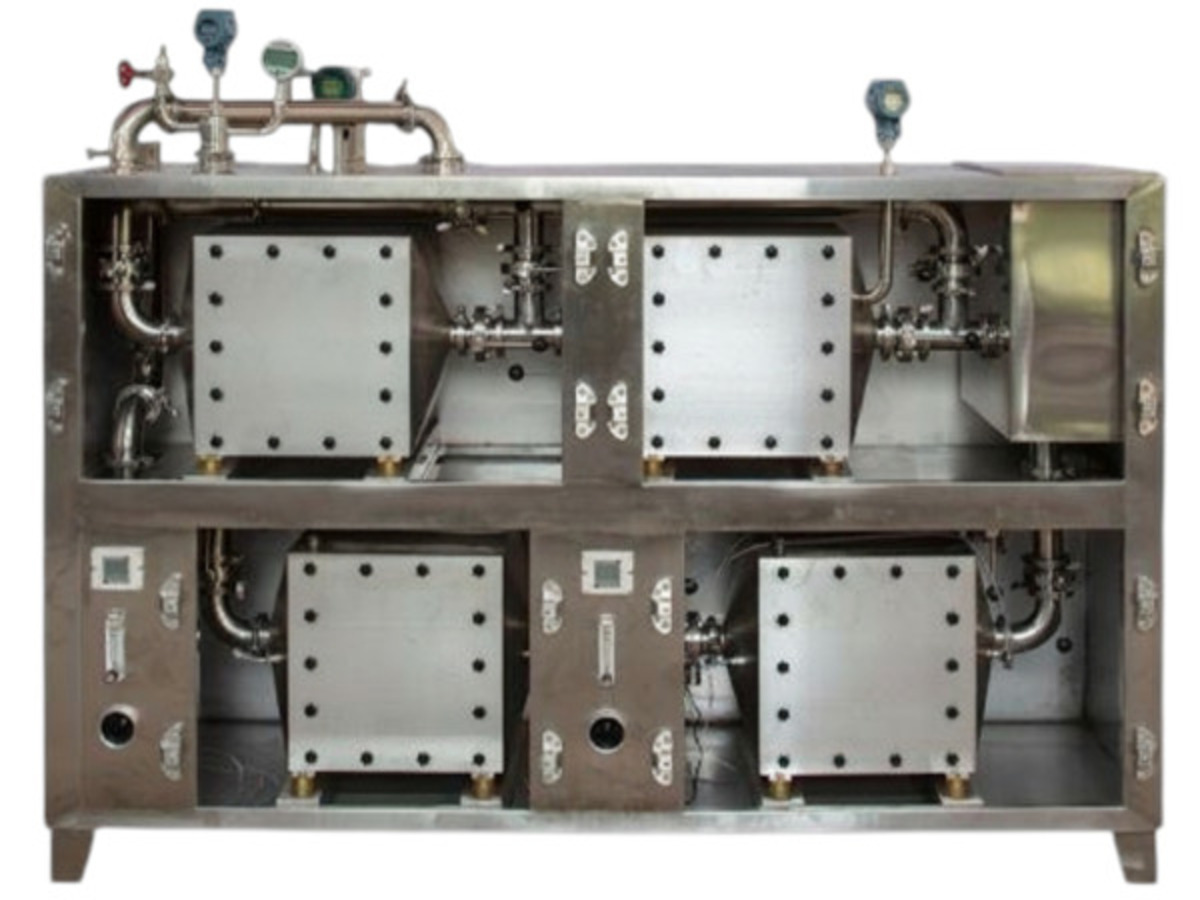

Figure 1: Complete system diagram showing dual absorption chambers, nitride removal unit, air dehydration system, electrical heating, blower, and comprehensive sensor monitoring network

Detailed breakdown of each system component with technical specifications and capabilities

Flexible system design suitable for diverse applications from academic research to industrial processing

Ideal for chemical engineering, environmental science, and nuclear engineering departments. Students can study adsorption kinetics, compare media performance, conduct breakthrough experiments, and collect data for research publications.

Used in nuclear research facilities, environmental testing laboratories, and safety demonstration projects. The comprehensive monitoring and dual-chamber design allows for validation studies, regulatory compliance testing, and technology development.

Applied in pharmaceutical manufacturing, chemical processing, and nuclear decommissioning projects. The system can be configured for continuous operation with redundant safety systems, automated controls, and compliance monitoring for regulatory requirements.

Excellent for hands-on learning in engineering and technology programs. The transparent components, comprehensive instrumentation, and modular design provide students with practical experience in air pollution control, process engineering, and instrumentation.

Complete system specifications and performance parameters

Real-world installations and implementation examples

Complete system installed in a chemical engineering research lab at a major university. Note the transparent viewing windows on absorption chambers and comprehensive instrumentation panel.

Detailed engineering diagram showing complete system layout, component interconnections, sensor locations, and process flow directions for both research and industrial configurations.

Touchscreen HMI interface showing real-time system monitoring, historical trend data, alarm status, and control parameters. The interface is designed for both research data collection and industrial operation.

Common questions about our dual-chamber iodine absorption systems

Our dual-chamber iodine absorption system is specifically designed for academic research environments with several key features:

The integrated nitride removal unit is a critical component that operates upstream of the iodine absorption chambers. Its function and operation include:

Yes, the system is specifically designed for dual-purpose use with features that support both research and industrial applications:

For Research Applications:

For Industrial Applications:

The system can be configured at purchase for either primary use case, or supplied with dual-mode capability.

The system includes a comprehensive sensor network with monitoring capabilities for all critical parameters:

All sensor data is collected through a centralized PLC system with options for real-time monitoring, historical trend analysis, data logging, and remote access. The system provides both local display on the HMI and remote access via web interface or mobile application.

Contact our engineering team for a custom quote, technical consultation, or system demonstration. We provide complete solutions for university research laboratories, government facilities, and industrial applications.